Selective Pallet Racking is a cost effective storage system providing direct access to all pallets. It provides high capacity storage, is easily installed and adjusted, and has low equipment and capital costs.

- Catalogue: Pallet Racking, Products, Racking Systems

Product Description

Selective Pallet Racking is the most versatile warehouse storage solution.

In modern warehousing, efficient space management and quick product accessibility are key to maintaining smooth operations. Among all pallet racking systems, the selective pallet rack is one of the most widely used solutions due to its flexibility, easy access, and cost efficiency.

What is a Selective Pallet Racking?

A selective pallet racking is a type of warehouse storage system designed to provide direct access to every pallet stored. It is built with upright frames and horizontal beams that form multiple pallet levels. Forklifts can easily access any pallet directly from the aisle, making it ideal for facilities that handle various SKUs with frequent inventory turnover.

This warehouse selective pallet racking system is a practical choice for warehouses, logistics centers, and distribution facilities that need real-time inventory management and flexibility in storage layout.

Features of Selective Pallet Racking

Structure and Components

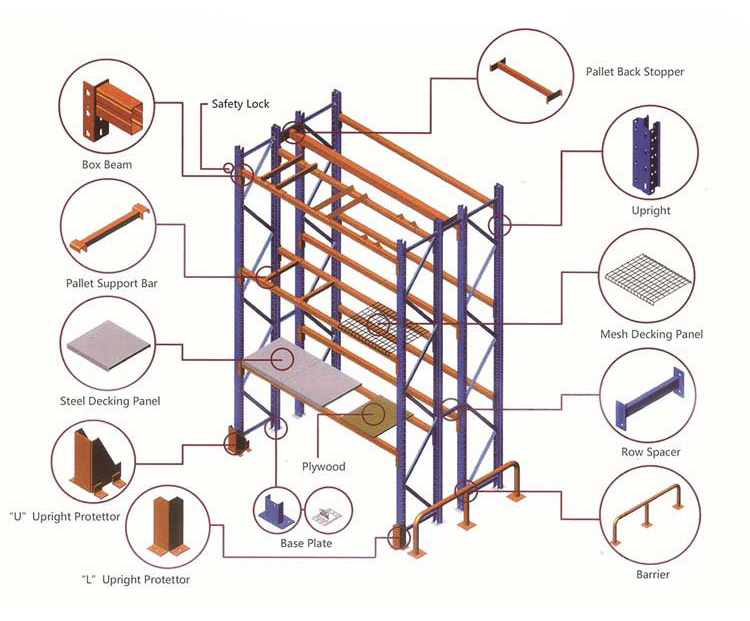

A selective pallet racking typically includes:

- Pallet Rack Upright Frames – Vertical structures that support the rack’s overall height and stability.

Sections:80*60/90*70/100*70/120*95

Features: made with mould; good loading capacity; easy assemble

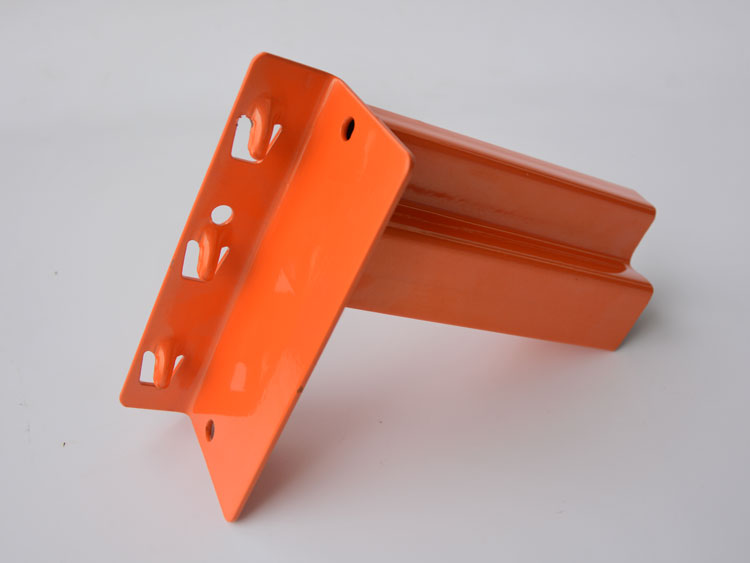

- Horizontal Pallet Rack Beams – Connect the uprights and hold the pallet loads.

Seticons: 50*80/ 50*100/50*120/50*140/50*160/40*80/40*100/40*120/40*140/40*60

- Safety pins and Accessories – Enhance safety and prevent beam dislodgement.

Advantages of Selective Pallet Racking

1. 100% Accessibility

Each pallet is stored in a single location and can be accessed independently without moving other pallets. This ensures complete SKU selectivity, reducing picking time and increasing warehouse productivity.

2. Flexibility and Compatibility

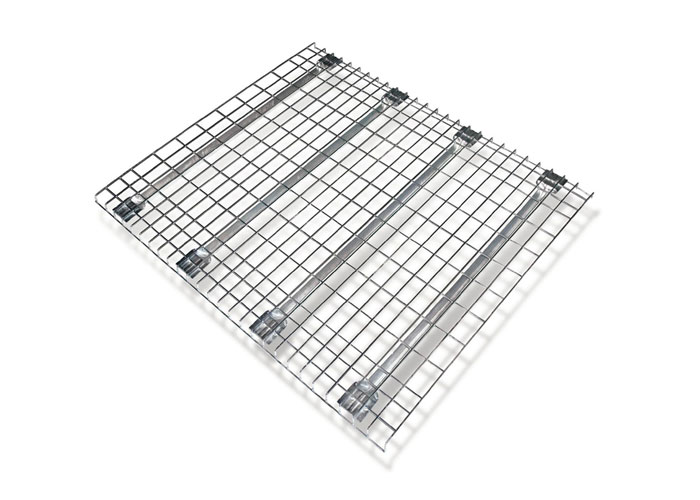

The selective pallet rack system can be easily customized for different pallet sizes, load capacities, and warehouse layouts. It can also be combined with wire decking, pallet supports, or safety bars for added functionality.

3. Cost-Effective Storage

Compared with high-density systems, selective pallet racking has a lower initial cost and simpler maintenance. Its modular design allows gradual expansion without major reconstruction.

4. Easy Inventory Control

Because each pallet position is clearly visible, warehouse operators can quickly count and identify products. This transparency enhances inventory accuracy and order fulfillment speed.

Limitations of Selective Pallet Racking

Although selective pallet racks are versatile, they have a few limitations:

- Lower Storage Density – Requires multiple aisles, which reduces total cubic utilization compared to drive-in or shuttle systems.

- Space Requirement – Suitable for warehouses prioritizing accessibility over maximum storage volume.

- Aisle Width – Standard forklifts need wide aisles, which can limit layout flexibility in small facilities.

To address these challenges, narrow-aisle or double-deep selective racking options can be used for higher density.

Applications of Selective Pallet Racking

Selective pallet racks are used in a wide range of industries, including:

- Retail Distribution – For storing varied SKUs and fast-moving consumer goods.

- Food and Beverage Warehouses – For managing perishable goods with FIFO flow.

- E-commerce Fulfillment Centers – To provide quick order picking and restocking.

- Manufacturing Plants – For keeping raw materials and finished goods organized.

The industrial selective pallet rack storage solution is ideal wherever SKU diversity and frequent pallet changes are daily requirements.

Design Considerations for Selective Pallet Racks

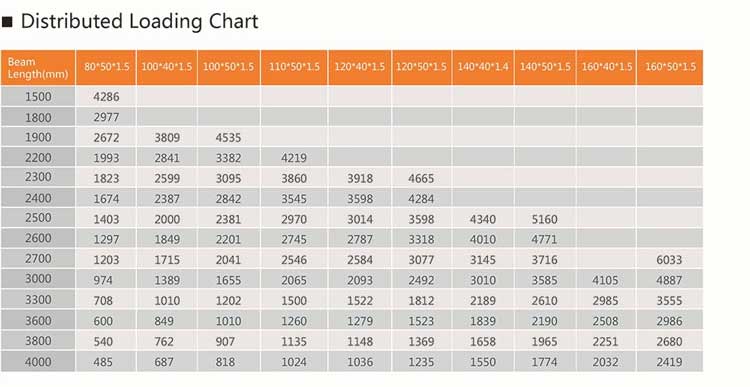

1. Load Capacity

Before installation, evaluate pallet weight and rack load capacity to ensure safety and performance. Overloading can lead to beam deflection or structural damage.

2. Aisle Width

Determine forklift type and turning radius to plan the proper aisle width. Narrow aisles can save space but require specialized equipment.

3. Beam Level Configuration

Adjust beam spacing based on pallet height and product type. Use wire decks or pallet supports for irregular loads or non-standard pallet sizes.

4. Safety Enhancements

Install column protectors, end-of-aisle guards, and safety pins to prevent damage from forklift impacts. Conduct periodic inspections and maintenance to ensure rack stability.

Selective Pallet Rack vs. Other Racking Systems

| Feature | Selective Pallet Rack | Drive In Rack | Push Back Rack |

| Storage Density | Medium | High | High |

| Accessibility | 100% | Limited | Partial |

| Inventory Rotation | FIFO | LIFO | LIFO |

| Cost | Moderate | Low | Moderate |

| Ideal Use | Mixed SKUs | Bulk Products | Medium Turnover Goods |

The selective pallet rack offers the perfect balance between accessibility and cost, making it a standard choice for many modern warehouses.

Installation Tips

For a safe and efficient heavy duty selective pallet rack installation, consider the following steps:

Site Planning – Measure ceiling height, floor load capacity, and available space.

Professional Design – Consult experts to create a customized layout that aligns with operational needs.

Proper Anchoring – Secure the rack base firmly to the floor to ensure structural stability.

Operator Training – Educate staff on safe loading, unloading, and forklift operation.

Regular Inspection – Schedule routine maintenance to detect wear or damage early.

A well-installed system ensures long-term durability and operational safety.

Packaging & Shipping:

FAQs About Selective Pallet Racking

Q1: What makes a selective pallet rack different from other systems?

It provides direct access to every pallet, making it suitable for warehouses that handle many SKUs with frequent picking.

Q2: Can it be used in cold storage?

Yes. With proper materials and coatings, selective pallet racks can operate in refrigerated or frozen environments.

Q3: How tall can a Selective Pallet Rack go?

The height depends on warehouse ceiling limits and forklift reach. Typically, systems can reach up to 12 meters or more.

Q4: Is it compatible with automated systems?

Selective racks can be integrated with warehouse management software and semi-automated picking systems for improved efficiency.

Q5: How long does it take to install?

Depending on the size and complexity, installation can take from a few days to several weeks. Professional installation ensures accuracy and safety compliance.

Contact Us for a Custom Storage Solution

If you’re planning to upgrade your warehouse with a selective pallet rack system, our team can design a solution tailored to your specific space, load requirements, and budget.

We offer:

✅ Professional layout planning

✅ Customized racking designs

✅ After-sales support

📞 Contact us today to discuss your warehouse project and receive a free design proposal that optimizes your storage efficiency!

Whatsapp/wechat/tell: +86-183-5022-2213

Email: [email protected]

.jpg)