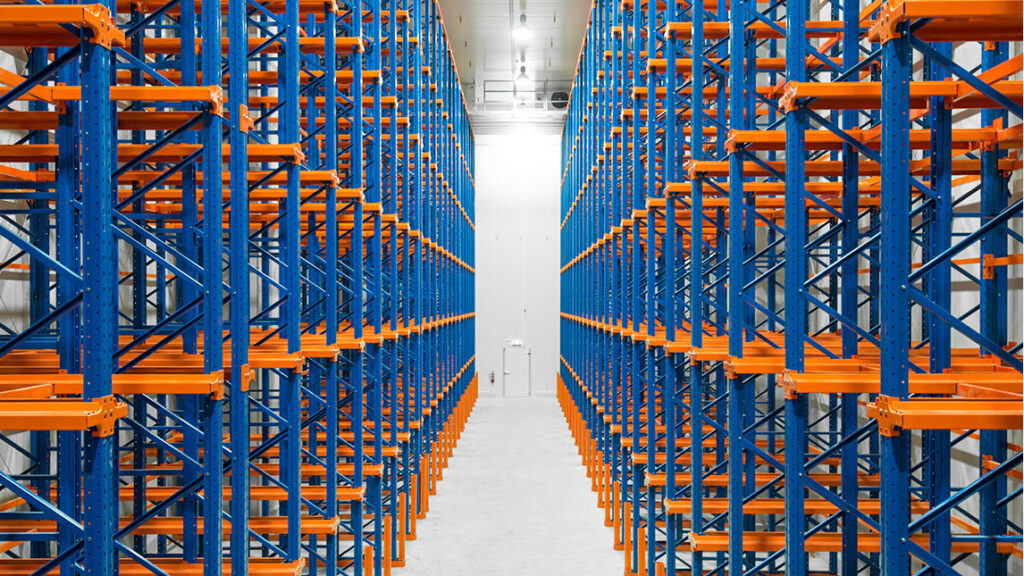

Drive-in racking system is ideal for stocking large quantities of relatively few items.

It can reduce overall square footage requirements by 35 percent or more compared to a standard selective rack configuration.

- Catalogue: Drive In Racking, Products, Racking Systems

Product Description

Maximize Your Storage Density with Drive-In Racking Systems

Is your warehouse space stretched thin while your inventory of homogeneous goods continues to grow? Our industrial drive-in racking systems are designed for high-density storage, allowing you to utilize every cubic foot of available space efficiently.

What is Drive-In Racking?

Drive-in racking is a high density storage system designed for high-volume inventory with a limited number of SKUs. Unlike traditional selective pallet racking, which has aisles between rows, drive-in racking allows forklifts to drive directly into the rack structure itself, eliminating most aisles.

This allows for a continuous storage flow with aisles only at the loading and unloading ends, significantly increasing your storage capacity within the same footprint.

Key Components of Drive-In Racking

Our systems utilize high-quality, heavy-duty components to ensure safety and durability:

Upright Frames:

A sturdy steel frame forms the system’s vertical structure and is designed to withstand extreme loads.

Horizontal Beams:

Attached to the columns of each storage level, it guides and supports pallets.

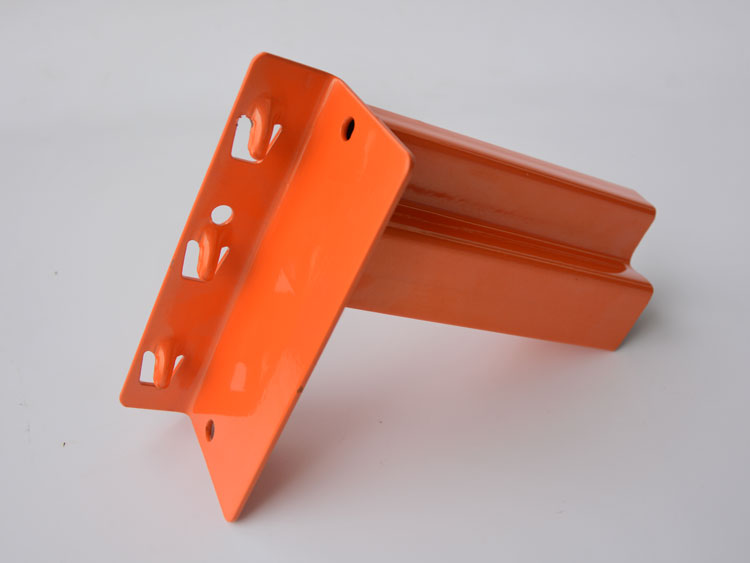

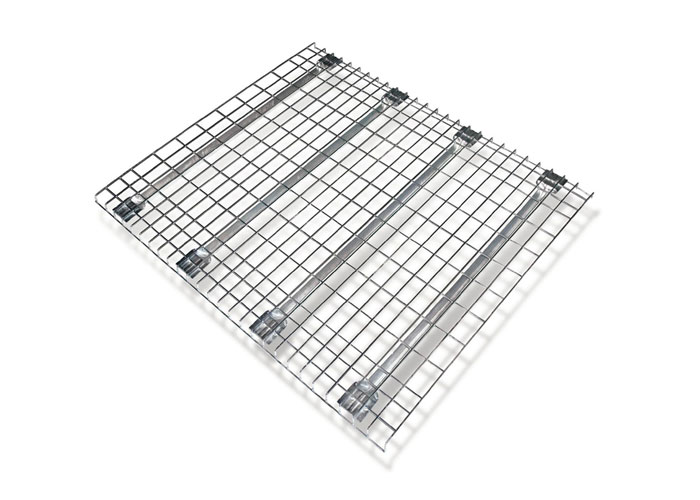

Pallet Support Channels:

Durable channels secure pallets within the racking level.

Corner Guards:

Protect the upright frame from forklift impacts and ensure safe and convenient entry and exit for forklift operators.

Features of Drive-In Racking

High-Density Design: Stores more pallets in a smaller space by minimizing aisle requirements.

LIFO Inventory Management: Typically operated on a “last-in, first-out” basis, it’s ideal for storing non-perishable goods or products with a long shelf life.

Heavy-Duty Construction: Constructed of high-grade steel, it can withstand significant static and dynamic loads.

Forklift Accessibility: Designed to be compatible with both standard counterbalanced forklifts and specialized narrow-aisle forklifts.

Customizable Layouts: We design each system to your specific warehouse dimensions, ceiling height, and load requirements.

Advantages of Drive-In Racking

Maximized Space Utilization

Increase your storage capacity by up to 75% compared to traditional single-deep racking.

Reduced Operating Costs

Reduced floor space usage lowers storage costs per pallet location and reduces overall facility costs.

Improved Organization

Ideal for storing large quantities of identical products, keeping inventory consolidated and manageable.

Enhanced Safety

Integrated safety features such as guide rails and anti-collision protection minimize the risk of accidents and product damage.

How Does Drive-In Racking Work?

Loading (Putaway)

A forklift enters the racking system’s open aisles. The driver first places a pallet on the rack’s deepest horizontal rails. The forklift then reverses out.

Storage

Pallets are stored sequentially, one at a time, on a single level.

Retrieval (picking)

To retrieve a pallet, a forklift enters the aisle. Because the first loaded pallet is at the rear, retrieval typically follows the last-in, first-out (LIFO) method. The driver picks up the last pallet loaded (the one closest to the aisle) and reverses out.

What Industries Are Drive-In Racks Suitable For?

Our drive-in racking is an ideal solution for any industry that needs to store large quantities of uniform products. Key industries include:

Refrigerated and frozen warehouses: Space is extremely expensive and efficiency is crucial.

Food and beverages: For storing large quantities of canned goods, beverages, or packaged foods.

Manufacturing: Ideal for raw materials or finished goods that are not SKU-diverse.

Bulk distributors: Companies that receive and ship full pallets of identical products.

Chemicals & Pharmaceuticals: For stable, non-perishable products stored in bulk.

Ready to transform your warehouse? Contact our storage experts today for a free consultation and a custom layout design to meet your specific needs.

.jpg)