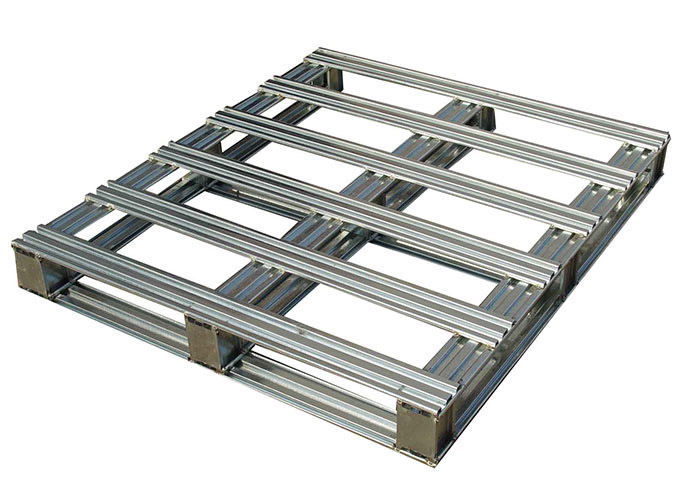

Galvanized pallet racking system:

H8000xD1100xW2700MM/6level

loading capacity 3000kgs/level

Total pallet position:8820 pallet position

- Catalogue: Pallet Racking, Products, Racking Systems

Product Description

Introducing the Ultimate Defense Against Corrosion & Wear, Maximize Storage & Longevity:

Upgrade your warehouse with our premium galvanized pallet racking, engineered with hot-dip galvanized steel frames for unmatched durability in demanding environments.

Built to withstand humidity, temperature fluctuations, and industrial wear, this pallet racking system delivers decades of reliable service while minimizing maintenance costs.

Feature Advantages

1. High Selectivity

Goods can achieve 100% selective access. Forklifts can directly reach each pallet position, which facilitates the quick and accurate access to specific goods and improves the efficiency of warehousing operations.

2. Strong Adaptability

It can be flexibly adjusted and combined according to the size and weight of goods, as well as the layout of the warehouse space. The galvanized pallet racking can meet the storage needs of different types of pallets and goods.

3. Corrosion-resistant and Durable

The galvanized frame has excellent rust-proof and corrosion-resistant properties. It can effectively resist the erosion of moisture, chemical substances, etc., and is suitable for various harsh environments, such as outdoors, cold storage, chemical warehouses, etc., thus extending the service life of the storage racks.

4. Safe and Reliable

It complies with relevant industry standards and specifications, and has a stable structure to ensure the safe storage of goods. Some storage racks are also equipped with racking accessories such as safety clips to enhance overall safety.

Guide to installation

Pre-installation Preparations

Before the installation, it is necessary to ensure that the warehouse site has been cleared, the ground is flat and solid, and there are good construction conditions.

Check whether the components of the arrived galvanized pallet racking system are complete, and see if there are any damages, deformations, etc. At the same time, prepare the tools and equipment required for the installation, such as forklifts, wrenches, screwdrivers, etc., and arrange professional installers.

Installation Process

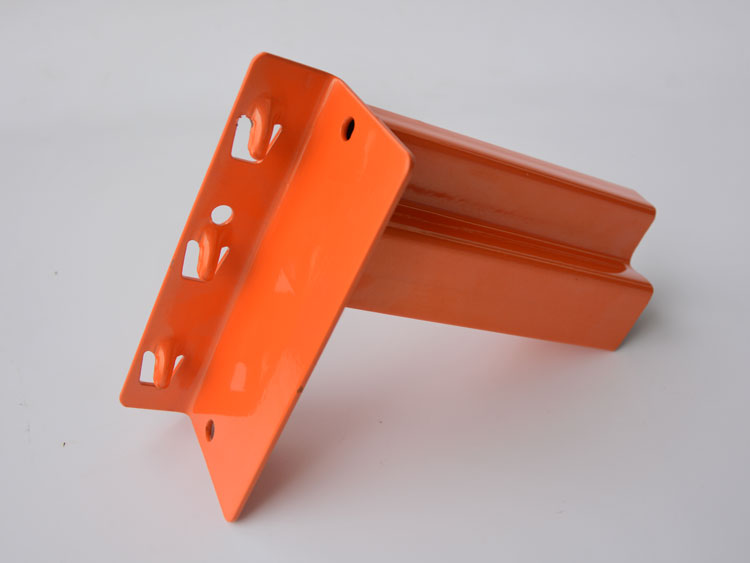

According to the design plan and installation instructions, first install the basic framework to ensure that the columns are vertical, the pallet rack beams are horizontal, and the connections are firm.

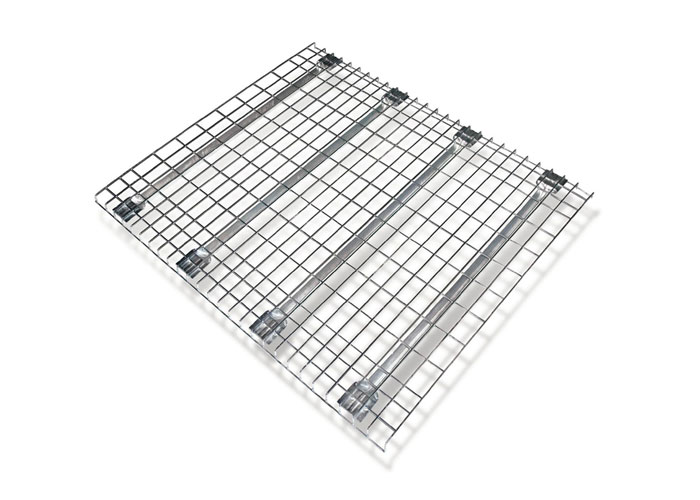

Then install the galvanized pallets onto the beams, adjust the position and spacing of the pallets to ensure the load-bearing capacity and stability of the pallets.

During the installation process, quality inspections should be carried out to promptly detect and correct installation deviations, ensuring that the installation quality meets the standards.

Post-installation Debugging and Acceptance

After the installation is completed, conduct debugging of the system. Check whether the forklift can smoothly enter and exit the pallet positions, whether the load-bearing capacity of the pallets meets the requirements, and whether the operation of the entire system is stable and safe.

Organize relevant personnel for acceptance, including the purchasing party, the user party, the installation party, etc. Conduct a comprehensive inspection of the galvanized pallet system following the contract requirements and quality standards. It can be officially put into use after passing the acceptance.

.jpg)