- Catalogue: Pallet Racking, Products, Racking Systems

Product Description

Maximize Your Storage Potential with Industrial Pallet Racks

Is your warehouse struggling with disorganized inventory and inefficient space utilization?

Our industry-standard pallet racking system is the ideal solution for businesses requiring direct, instant access to every SKU (stock keeping unit). Designed for flexibility, durability, and exceptional organization, it’s the backbone of warehouse optimization.

What is the Industrial Pallet Rack?

Industrial selective pallet racking is the most common and versatile storage racking system in today’s warehouses.

It’s designed to store palletized materials in multiple horizontal rows and multiple vertical layers, with each pallet individually accessible.

This “selective” access means you can access any pallet at any time without moving other pallets, making it ideal for high-turnover inventory and first-in, first-out (FIFO) operations.

Key Components of Industrial Pallet Rack

Our warehouse racking system is engineered from high-quality materials and includes the following core components:

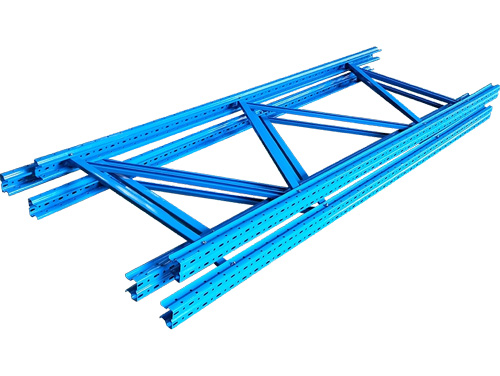

The vertical floor-standing structures that form the backbone of the racking system. They feature bracing for stability and punched holes for adjustable beam height.

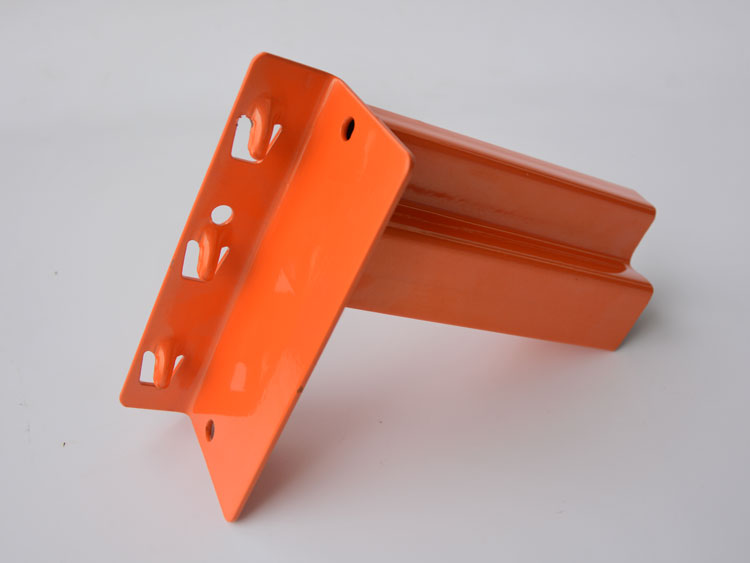

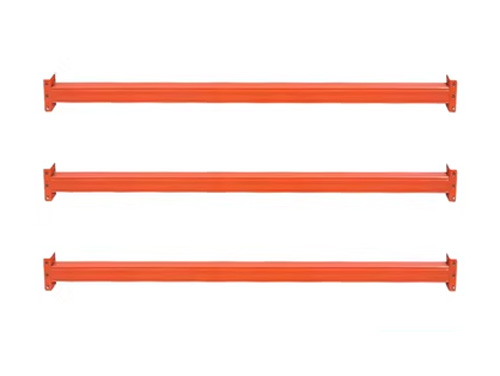

The horizontal arms are connected to the upright frame to support the pallet. They are equipped with pallet rack safety pins to ensure a secure connection.scing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Includes end-of-aisle guards, pallet rack post protectors and pallet supports to ensure a complete and safe installation.

Spacers and Base Plates

Ensure racks are vertical and firmly anchored to the concrete floor for maximum stability and safety.

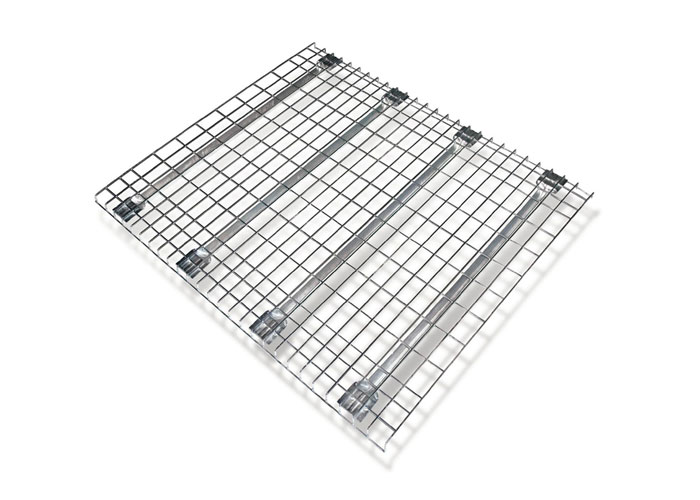

Optional component that provides a secure surface for palletized or non-palletized goods, improving safety and regulatory compliance.

Features of Industrial Pallet Rack

- Unrestricted Accessibility: Each pallet location is fully accessible, eliminating the need to stop for pickup.

- Fully Adjustable: Beam heights can be easily reconfigured without tools to accommodate inventory of various sizes, allowing your warehouse to adapt to changing needs.

- Easy Integration: Works seamlessly with all types of material handling equipment, including forklifts and pallet jacks.

- High Durability: Manufactured from high-grade steel, it offers a variety of load capacities and can easily handle even the heaviest unit loads.

- Scalable Design: The racking systems can be easily expanded upwards or outwards as your storage requirements grow.

Why Choose Our Racking System?

- Maximized Space Utilization: Efficiently use your warehouse’s cubic volume by building upwards, significantly increasing your storage capacity without increasing floor space.

- Improved Inventory Management: Direct access streamlines inventory rotation, cycle counting, and picking processes, increasing overall operational efficiency.

- Cost-Effective Solution: Provides an excellent return on investment through its durability, flexibility, and operational cost savings from improved workflows.

- Enhanced Safety: A well-designed and installed racking system, combined with optional wire mesh decks and pallet rack guards, creates a safer working environment for personnel and equipment.

- Versatility: Able to store a variety of products, from manufacturing parts and food to electronics and automotive supplies.

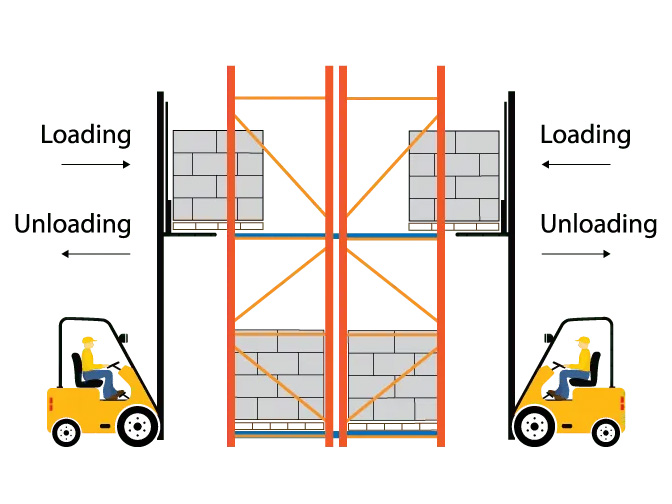

How Does Industrial Pallet Rack Work?

The operation is extremely simple and efficient:

Configuration:

The pallet rack upright frames are positioned and securely anchored to the floor. Then, insert the pallet rack beams into the holes in the uprights at the desired height to create a storage levels.

Loading:

A forklift or pallet jack lifts the loaded pallets directly onto the open racking beam. Each pallet rests on two parallel crossbars.

Retrieval:

When a specific pallet is needed, the forklift operator can drive the forklift directly to that location and retrieve it without disturbing surrounding pallets.

What Industries are Industrial Pallet Racks Suitable for?

The flexibility of industrial pallet racking makes it suitable for nearly any industry requiring organized bulk storage, including:

- Third-Party Logistics (3PL) & Distribution Centers

- Retail & E-commerce Fulfillment Centers

- Manufacturing & Assembly Plants

- Food & Beverage Warehousing

- Cold Storage Facilities

- Automotive and Aerospace Parts

- Consumer Goods and Appliances

Ready to optimize your storage space? Contact our team of experts today for a free, no-obligation consultation and customized quote based on your specific warehouse needs.

.jpg)