- Catalogue: Boltless Rivet Shelving, Products, Shelving

Product Description

The light duty boltless shelving is one of the commonly used storage shelf varieties, which is named after the way of rivet hangs between the beam and the column. The boltless industrial shelving does not need screws for assembly. It has the characteristics of convenient and quick installation and disassembly, and the assembly is changeable. Boltless shelving is suitable for storing some light and small goods. The shelf load is less than 180kg/layer, which is a light duty storage shelf.

Structure of Boltless Shelving

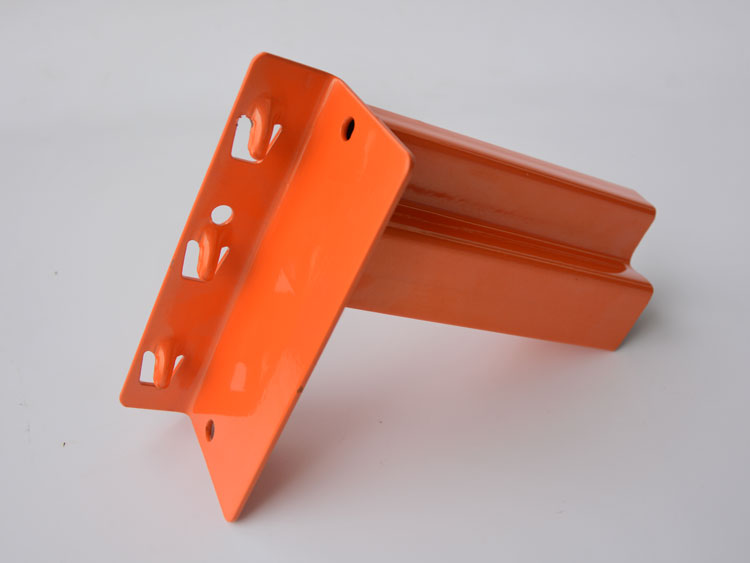

1. Shelf buckle structure, easy to disassemble; equipped with plastic feet at contact with the ground;

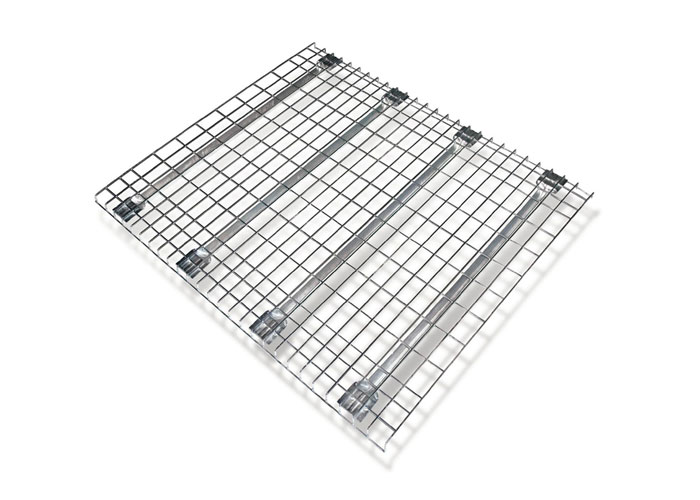

2. The shelf column is made of equilateral angle steel with bilateral punching holes. The distance between the holes is arranged in a straight line at a distance of 50mm. The column holes are used to connect the laminates;

3. The shelf steel plate is made of the cold-rolled steel plate and bent on four sides according to the required size. Laminates can be selected from steel laminates or wood laminates;

4. The upright column and the steel laminate are connected and fixed by the quick-buckle pin and the triangular fixed piece;

5. After the light duty boltless shelving parts are processed and formed, the finished products are assembled after grinding, pickling, phosphating, powder electrostatic spraying, drying, and other processes. The surface of the finished shelf produced is smooth and beautiful; the laminate can be adjusted up and down, and it is easy to disassemble and assemble.

Specification of Boltless Shelving

SIZE D*W*H mm | LAYERS | LOAD CAPACITY | COLOR |

D300×W700×H1600mm | 5 | 100kgs/shelf | White, dark grey, black,blue,orange, Customized |

D300×W700×H1524mm | 4 | 70kgs/shelf | |

D400×W800×H1600mm | 5 | 100-150kgs/shelf | |

D400×W900×H1828mm | 5 | 100-150kgs/shelf | |

D400×W1200×H1828mm | 5 | 100kgs/shelf | |

D450×W900×H1828mm | 5 | 150kgs/shelf | |

D450×W1200×H1828mm | 5 | 150kgs/shelf | |

D600×W900×H1828mm | 5 | 100kgs/shelf |

Production Process of Boltless Shelving

① The specifications of the boltless shelf column are 30×30mm angle steel profiles, which are made of strip steel that is flattened, rolled by a rolling mill, punched by a punch, and then cut according to the specified height.

②The shelf laminate is made of a cold plate, which is made by flattening, slitting, bending and welding reinforcing ribs.

③After the shelf column and the laminate are processed into semi-finished products, the latter process can be sprayed. After completion, it can be packaged and shipped.

④The boltless industrial shelving is one of the ideal substitutes for the simple shelf that replaces the original enterprise with angle steel welding and the beam is covered with wooden planks. The product has the advantages of low cost, simple assembly, and disassembly, and can be used alone.

⑤The boltless shelves can be designed and manufactured according to the actual storage space.

Installation of Boltless Shelving

Application of Boltless Shelving

1. The light duty boltless shelving is usually used for small and medium-sized goods storage, such as electronics, light industry, supermarkets, culture and education, household, hotels, etc.; the single-layer load-bearing is preset within the range of 180kg.

2. Mainly based on manpower, manual handling, storage, and picking operations.

Packaging and Shipping of Boltless Shelving

.jpg)