Product Name: C beam grey blotless shelving with steel board

Depth: 300-600mm

Width: 700-1200mm

Height: 900-1828mm

Weight Capacity: 70-150 kgs/shelf

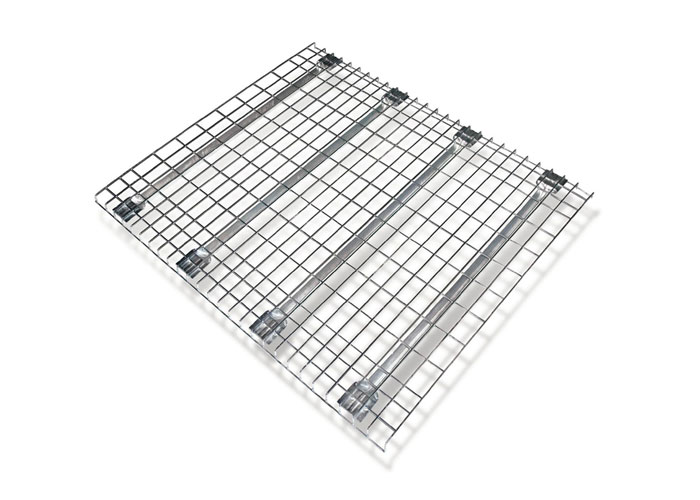

Board Type: MDF board, laminated board, steel board

Color: White, dark grey, black, or Customized

- Catalogue: Boltless Rivet Shelving, Products, Shelving

Product Description

Boltless steel shelving, commonly referred to as boltless rivet shelving, are easily assembled and reconfigured without any hardware, nuts or bolts. Boltless shelving system is a form of industrial storage without nuts or bolts.

This type of boltless steel shelving unit is designed to be easy to assemble. You can adjust and reconfigure boltless steel shelving units quickly and easily, making them a versatile choice for any warehouse or storage space. Boltless steel shelving is durable, easy to configure and versatile, making them a great storage shelving solution for any facility.

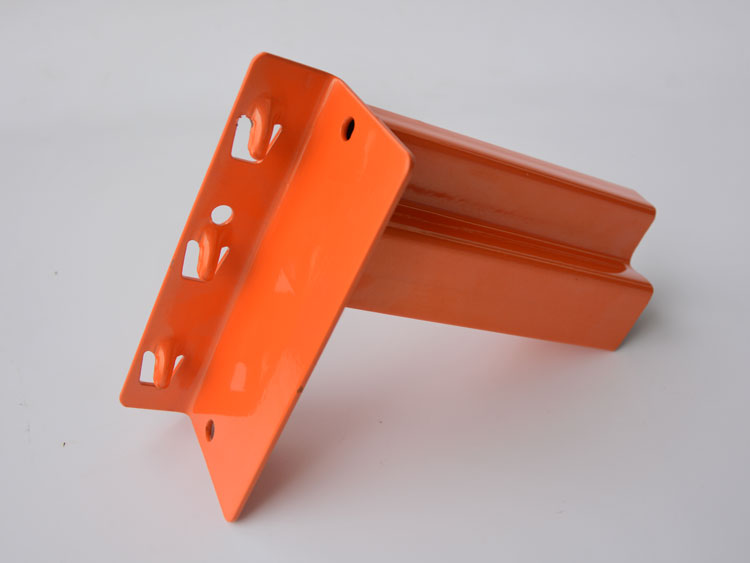

Structure of Boltless Steel Shelving

The structure is convenient for disassembly and assembly; plastic feet are used to contact with the ground.

Posts are made of equal-angle angle steel through punching holes, the hole distance is arranged in a straight line at a distance of 50mm, and the post holes are used for hanging laminates.

After the various parts of the boltless steel shelving are processed and shaped, they are all assembled after grinding, pickling, phosphating, automatic powder electrostatic spraying, and drying. The surface of the produced boltless steel shelving products is smooth and beautiful, and the boltless steel shelving units can be adjusted up and down arbitrarily, which is convenient for disassembly and assembly.

Details of Boltless Steel Shelving

Application of Boltless Steel Shelving

Boltless steel shelving is usually used for small and medium-sized items and lighter cargo storage. The single-layer load bearing is expected to be within 180kg.

The boltless shelving systems are mainly operated by manpower, manual handling, warehousing and picking.

.jpg)