- Catalogue: Products, Racking Systems, Radio Shuttle Racking

Product Description

The automatic shuttle racking system is a high-density compact storage solution that uses powered shuttles to automatically carry loads into the rack. The pallet shuttle, which is controlled by a wireless remote, takes the pallets in and out of the storage racking system. The forklift doesn’t need to enter the storage area. The first pallet’s location at either end is where the forklift loads and unloads the goods. Hence, there is optimum use of storage space, and workplace accident rates are also reduced.

Features & Benefits of Shuttle Racking System

(1)FIFO or FILO, Optional;

(2) Elegant appearance, sturdy and durable;

(3) The racking system is also speedily installed and simple to adjust;

(4) The beam levels are adjustable by 50mm,50.8mm,75mm, and 76.2mm;

(5) Individual access to all pallets to the full height of the warehouse;

(6) Lower level pallets can be located on the floor picking pallets;

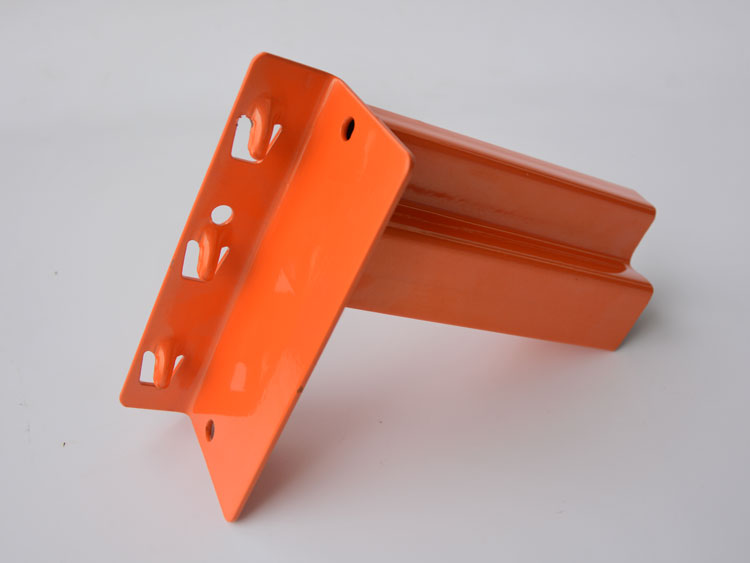

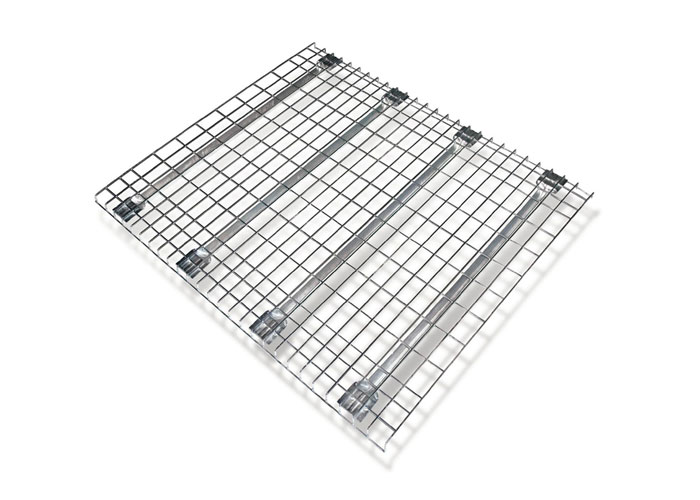

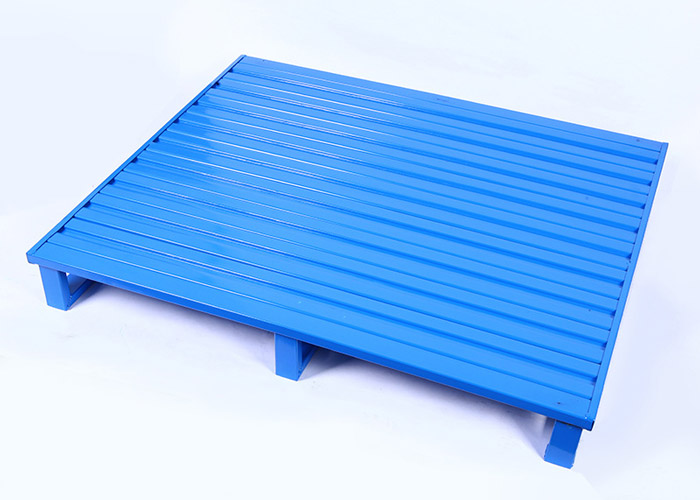

(7) Accessories available can accommodate every unit load type;

(8) goods can be stored in the warehouses with the highest density and low cost;

(9) better safety and anti-seismic performance than drive-in racks;

(10)as each pallet only needs to be positioned at the beginning of the deep lane storage it increases efficiency within operations.

.jpg)