Push Back Pallet Racking are a perfect way to take optimal advantage of your warehouse while not having to slow product rotation or increase handling time. With the push back pallet racking system, the warehouse can store a larger number of pallets while maintaining more pallet positions than other high-density systems such as drive-in racking.

- Catalogue: Products, Push Back Racking, Racking Systems

Product Description

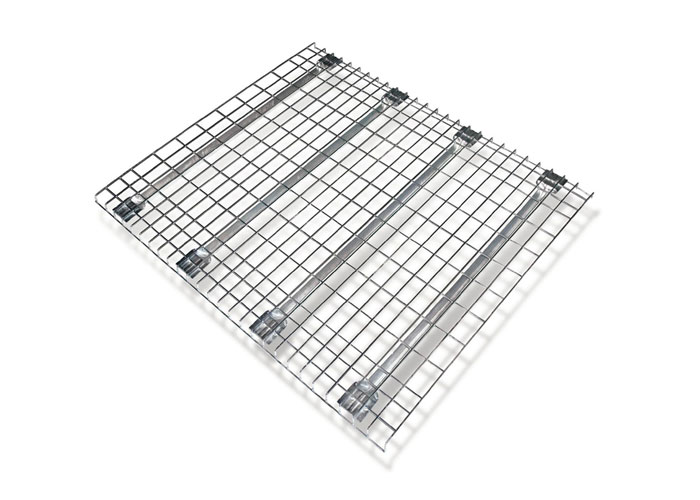

Push-back pallet racking is a live storage racking system for the accumulation of pallets. Multi-layer dollies are overlapped between the front and rear beams, and the stacked goods are pushed into the dollies from the outside, after which the stored goods will push the original goods inside.

The warehouse push back pallet rack system provides up to 90% more storage space than standard selective racks. That is the reason why this kind of dynamic pallet storage system is becoming more and more popular, and it quickly becomes the preferred storage method in many sectors.

Features of Push-Back Pallet Racking

- 1. Push-back pallet racking comprises specific structural parts such as pallet trolleys. The pallet trolleys have flowable characteristics, and goods are specified to enter and exit at one end of the storage racking and follow the first-in, last-out sequence.

- 2. When storing and transporting goods, the forklift is only located at the lower level end of the shelf channel, without entering the shelf goods storage channel. This kind of shelf has the typical characteristics of high density, fast storage, and transportation.

- 3.Usually used for occasions where storage space is extremely limited, but storage capacity must be increased or there is a time requirement for goods, etc. The requirements for goods picking are not high.

Specifications of Push-Back Pallet Racking

| Dimension & Load Capacity | Length:1500-3600mmDepth: 400-1500mmHeight: 1000-11,000mmLoading capacity: 500-4000kg /levelSpecial size and loading capacity are also available |

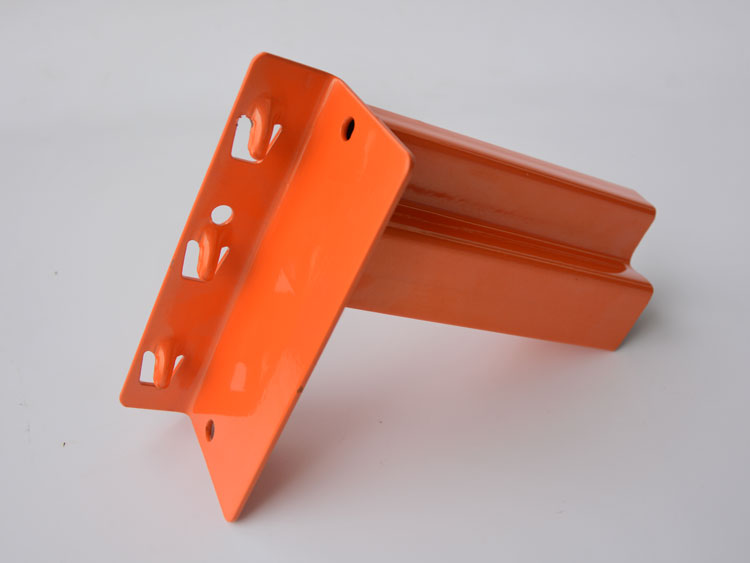

| Main Parts Specs | Upright section: 80*60*2.0, 90*60*2.0, 90*70*2.0,100*70*2.0, 120*75*2.0 etcBox beam section: 80*50*1.5, 100*50*1.5, 110*50*1.5, 120*50*1.5, 140*50*1.5, 160*50*1.5, 140*50*2.0, 160*50*2.0 etcHorizontal & diagonal braces, upright footplates, safety locking pins, bolts & nuts, anchors and all necessary components |

| Color | RAL7035, RAL7001, RAL6021, RAL5015, RAL1023, RAL1007, RAL2004 or your requirement |

| Quick delivery | Within 25 days for ordinary order quantity |

Advantages of Push-Back Pallet Racking

- 1. When the number of pallets of a product is large and does not require “first-in-first-out”, it can simplify the work process, and the benefit is very significant.

- 2. It shortens picking time and does not require special handling equipment.

- 3. Since there are more storage areas and fewer aisles, space utilization and productivity are high.

- 4. can avoid high-density storage racks in the loading and unloading operations often prone to cargo damage.

Sample CAD layouts of Push-Back Pallet Racking

Usage of Push-Back Pallet Racking

- 1. Forklift access.

- 2. Suitable for small variety and a large number of goods, first-in, last-out operation method.

- 3. Suitable for freezer storage and other cases that need to improve space utilization.

Packaging & Shipping:

Aceally pay great attention to export package ,which aims at protecting our goods from being damaged during transportation, loading or unloading.Our packs can use forklift to unload the container easily and such can be able to greatly save labour cost.

If you are looking for warehouse storage push back pallet racking design or more information, please call us now and we will work with you to provide a layout and budget for your warehouse.

.jpg)