Warehouse Heavy Duty Storage Steel Selective Pallet Racking

Catalogue:

Product Description

Selective Rack Features & Advantages:

Selective Pallet rack Beams:

Selective Rack Uprights:

Selective Rack Beam Post Distributed Loading Chart:

Packaging & Shipping:

Product Description

Aceally Selective Pallet Racking is the most common type of warehouse racking; it has the lowest pallet storage capacity but is also the lowest cost per square metre of racking. However, in terms of high volume storage greater than 3000 pallets, it’s often the most expensive solution.

Selective Rack System Layout:

Selective Racking is only one pallet deep; with a maximum of two racks being able to be placed back to back.

Selective Pallet Racking System Access (FIFO):

Selective Pallet Racking system provides direct access to every pallet in storage. For low turnover volume & high differentiation product lines this type of racking is a must.

This means it’s a First In First Out (FIFO) racking type (meaning the stock added in first is also removed first, compared to Last In First Out (LIFO) systems. (Which means that pallets are inaccessible until all the newer stock is removed (see Push Back Racking as an example of LIFO)?

FIFO ensures that perishable or short shelf life SKU’s are able to be turned over effectively.

Aisle Width:

When it comes to Selective Pallet Racking; aisle width is a major factor for storage capacity. Storage capacity can be as low as 35% to as high as 75% depending on the type of pallet handling equipment you choose (take a look at this basic layout guide to get an idea.

Narrow width aisles don’t always equal lower storage cost. Narrow width aisles lower the forklift operator’s margin of error. This can lead to slower handling times which can outweigh the benefits associated with greater storage. Ensure you compare these costs before making a decision.

Selective Rack Features & Advantages:

- Access large range of Stock Keeping Units (SKU’s)

- First In First Out (FIFO) inventory management.

- Cheapest type of racking (Per square metre)

- Multiple access (more than one truck in same aisle)

- No special truck requirements

- Lower Forklift or Pallet Handling costs; as standard forklifts are cheaper than specialised equipment.

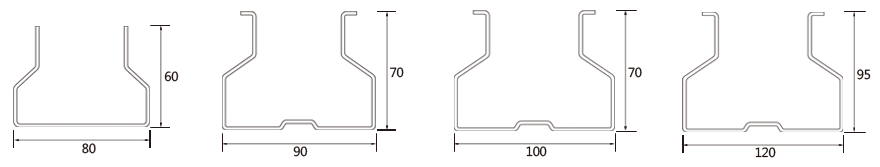

Selective Pallet rack Beams:

Sections:80*60/90*70/100*70/120*95

Features: made with mould; good loading capacity; easy assemble

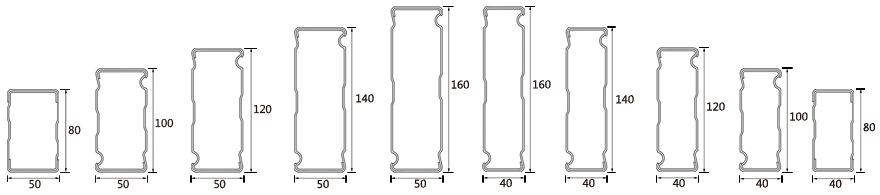

Selective Rack Uprights:

Seticons: 50*80/ 50*100/50*120/50*140/50*160/40*80/40*100/40*120/40*140/40*60

Selective Rack Beam Post Distributed Loading Chart:

| UPRIGHT LOADING TABLE | ||||||||||

| 80x60x1.8 8500KG/BAY | ||||||||||

| 80x60x2.0 9400KG/BAY | 100x70x1.8 11800KG/BAY | |||||||||

| 90x70x1.8 10000KG/BAY | 100x70x2.0 13500KG/BAY | |||||||||

| 90x70x2.0 11800KG/BAY | 100x70x2.3 15000KG/BAY | |||||||||

| 90x70x2.5 15000KG/BAY | 100x70x2.5 16300KG/BAY | |||||||||

| BOX BEAM LOADING TABLE | ||||||||||

| Beam length (mm) | 80*50*1.5 | 100*40*1.5 | 100*50*1.5 | 110*50*1.5 | 120*40*1.5 | 120*50*1.5 | 140*40*1.4 | 140*50*1.5 | 1*40*1.5 | 1*50*1.5 |

| 1500 | 4286 | |||||||||

| 1800 | 2977 | |||||||||

| 1900 | 26 | 3809 | 4535 | |||||||

| 2200 | 1993 | 2841 | 3382 | 4219 | ||||||

| 2300 | 1823 | 2599 | 3095 | 38 | 3918 | 4665 | ||||

| 2400 | 1674 | 2387 | 2842 | 3545 | 3598 | 4284 | ||||

| 2500 | 1403 | 2000 | 2381 | 2970 | 3014 | 3598 | 4340 | 51 | ||

| 20 | 1297 | 1849 | 2201 | 2745 | 2787 | 3318 | 4010 | 4771 | ||

| 2700 | 1203 | 1715 | 2041 | 2546 | 2584 | 3077 | 3716 | 4425 | 5068 | 33 |

| 3000 | 974 | 1389 | 1655 | 2065 | 2093 | 2492 | 3010 | 3585 | 4105 | 4887 |

| 3300 | 708 | 1010 | 1202 | 1500 | 1522 | 1812 | 2189 | 2610 | 2985 | 3555 |

| 30 | 0 | 849 | 1010 | 12 | 1279 | 1523 | 1839 | 2190 | 2508 | 2986 |

| 3800 | 540 | 762 | 907 | 1135 | 1148 | 1369 | 1658 | 1965 | 2251 | 2680 |

| 4000 | 485 | 687 | 818 | 1024 | 1036 | 1235 | 1550 | 1774 | 2032 | 2419 |

Packaging & Shipping:

Packaging:

- The main packing is a standard export carton or can use wooden or steel pallets, also can according to customer’s requirement

- Uprights packing by bubble foam or paper slip, layer boards packing in a carton, each part packed separated

- Help you to print shipping marks and logos on the cartons.

- Packing details as customized.

Shipping terms:

- Loading port: Shanghai, Nanjing,China main port.

- Sample delivery: 7-10days

- Mass production delivery:20-25days for one 20’GP,30days for one 40’HQ.

- We accept FOB, CIF, CFR price, can quote you shipping charge for your reference.