- Catalogue: Products, Push Back Racking, Racking Systems

Product Description

Push back pallet racking system is also known as reverse gravity rack. Push back rack allows for a “Last in, First out” (LIFO) rotation inventory management system as well as a reduction in the number of fork truck aisles needed in your rack warehouse. This translates into increased productivity, efficiency (time savings) and optimizes your existing space.

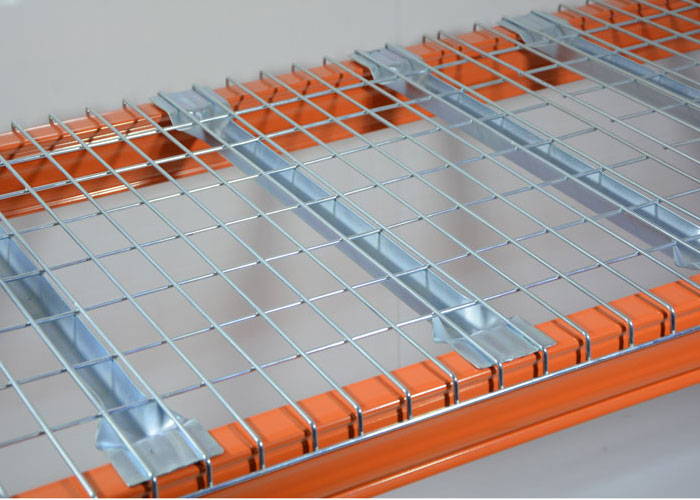

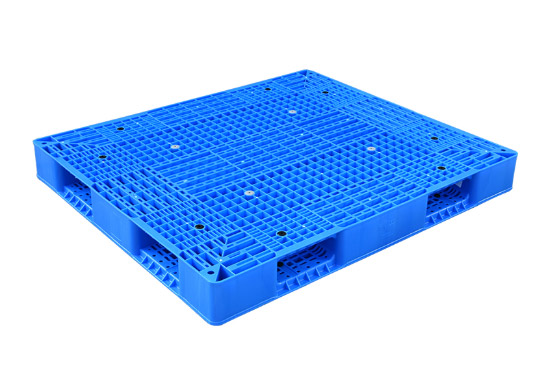

Loads pallets are stored and retrieved from the aisle. Loads in each push back rack lane rest on a cart, which sits atop a rail that slopes gently toward the front (towards the aisle).

When a new load pallet is deposited onto a cart within a lane by a forklift, it “pushes back” the one already at the face as well as those behind it. Depending on how “deep” (2 deep to 6 deep) the storage rack is will determine how many pallets can be stored in that individual lane.

Then, when a load/pallet is picked from the face of the rack or lane, the contents of the lane all move gently forward (at a controlled and slow speed) with a new pallet coming to the face, replacing the one just removed.

This new pallet (which moved forward) is now also ready to be picked, or another pallet can be added (“pushed back”) to fill the lane again.

Features of Push Back Pallet Racking System

- LIFO;

- Large storage quantity;

- High efficiency of space utility;

- Suitable for storing varieties;

- Store a large number of cargos;

- Suitable for cold storage improving the density.

Please provide the following information so as to get a fast quotation,

A) The warehouse layout plans

B) The size of shelving(length*width*height)

C) How many bays do you want

D) How many layers for each bay that you want

E) The loading capacity of each layer

F) The color you want