The mezzanine floor is used for mezzanine support in the case of limited plant space and can design multiple layers (usually 2 to 3 layers) of warehouse storage racks, the industrial mezzanine floor can use stairs or a hydraulic lifting platform as climbing facilities and each floor can be placed different goods.

- Catalogue: Mezzanine Floor, Products, Racking Systems

Product Description

The warehouse industrial mezzanine floor system is designed to provide elevated space within existing buildings without the cost and disruption of full construction.

A mezzanine floor can dramatically increase usable area in a warehouse, factory, or logistics center. Mezzanine is a freestanding intermediate level constructed within a building’s existing vertical space.

Features of mezzanine floor system

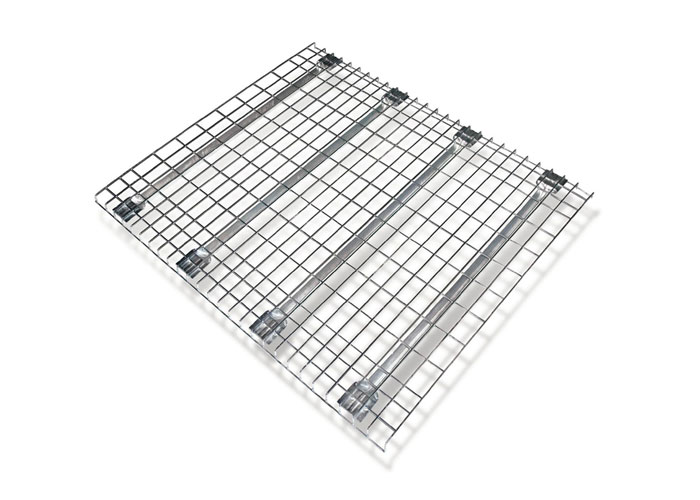

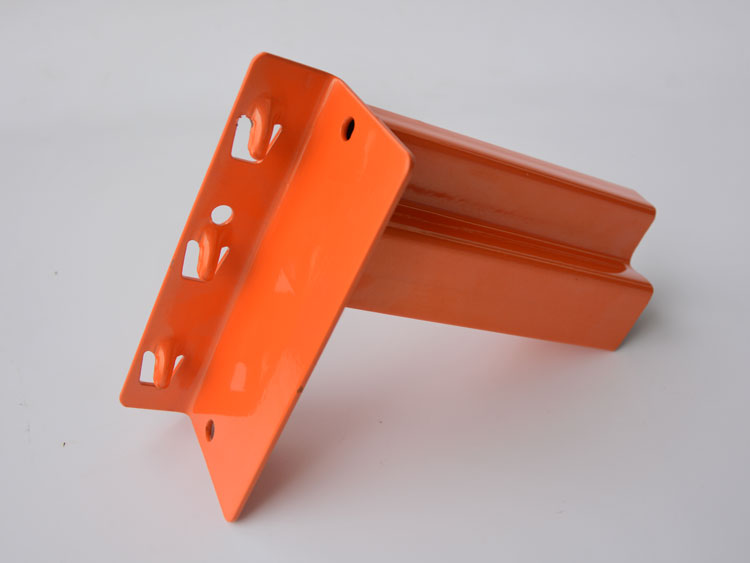

Modular steel structure: columns, primary beams, secondary members, and deck form the framework. As stated, the mezzanine uses “engineered support systems—typically steel columns or frames” to support loads.

Versatile decking options: steel deck (solid plate or grating), wood or composite boards, depending on application and load.

Access integration: stairs, handrails, gates, lifts or conveyor openings can be included for safe personnel or goods access.

Custom sizing and load-rating: The system is built to match your warehouse’s dimensions, load demands and layout constraints. Our industrial storage systems can be customized to meet your specific load requirements and support heavy machinery, equipment platforms, or storage areas.

Specification of mezzanine floor system

| Product Name | Warehouse Industrial Mezzanine Floor System |

| Customized Specification | Rack Supported Mezzanine is available in a range of sizes and configurations. Please call or email us and we can work together to get the most cost-effective and practical solution. |

| Upper/Lower Rack Levels | 2 levels, 3 levels, 4 levels, 5 levels |

| Rack Load Capacity | 300KG, 500KG, 700KG, 1000KG, 1500KG per level |

| Catwalk/Aisle Width | 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm |

| Aisle Flooring Load Carry Capacity | 300KG, 500KG, 600KG per square meter |

| Raw Material | high quality cold rolling steel Q235B(SS400) purchased |

| Material Thickness | 1.5mm, 1.8mm, 2.0mm, 2.5mm |

| Surface Treatment | deoil, derusting and powder coat paint finish |

| Mezzanine Colors | standard blue, orange and customized available |

Applications of mezzanine floor system

Expanding storage capacity in a warehouse by adding an elevated floor above existing pallet racking or open space.

Creating multi-tier platform levels for picking, packing, or assembly operations, thereby optimizing floor space.

Providing elevated workstations, offices, or quality control zones above the main floor while keeping the ground footprint clear.

Supporting conveyors, machinery, or other installations that require elevated platforms or walkways.

Why It Matters?

In many warehouses, the available headroom or vertical space goes unused. Installing a mezzanine floor allows you to convert this under-utilized vertical volume into a productive area. Installing a mezzanine floor can significantly boost productivity, improve accessibility, and enhance workplace safety.

By choosing the right mezzanine floor system—for example, one sized and rated for your load profile—you ensure that your storage infrastructure supports your operations rather than limiting them.

Benefits of mezzanine floor system

Maximising Volume and Storage Density

By deploying the system above the existing floor footprint, you effectively increase usable square footage. This is especially beneficial in warehouses where expanding outwards is cost-prohibitive. The warehouse industrial mezzanine floor system installation guide addresses how to maximise volume while retaining accessibility and safety.

Custom Fit for Operational Workflow

Because the mezzanine floor system can be tailored (beam spacing, deck type, access points), it aligns with your picking, storage or manufacturing process. For example, a multi-tier warehouse mezzanine platform for storage expansion allows separation of picking levels, overflow storage or dedicated packing zones.

Cost-Effective Alternative to New Construction

Instead of a new building or extension, adding a mezzanine is faster and less disruptive. The steel mezzanine floor system for pallet rack supported warehouse enables you to integrate with existing racking systems and utilise structural headroom with minimal disruption.

Safety and Compliance

A well-designed system includes structural verification, proper load rating, safe access and compliance with local building or fire codes. Many systems are prefabricated and bolted together for predictable performance and installation quality.

Scalability and Future Flexibility

If your inventory, process or footprint changes, a mezzanine floor system offers reconfiguration potential. Multi-tier layouts can adjust, deck types can change, and access can be diversified to accommodate new workflows.

Key Considerations of Choosing the Right Racking System

Load calculations: Understand the dead load, live load and equipment load your mezzanine must support.

Clear height and headroom: Ensure enough clearance from floor to ceiling for shelving, equipment or forklifts.

Deck type and finish: Choose the right deck material (steel plate, grating, etc.) for your handling method.

Access design: Consider stairs, lifts or conveyor openings to optimise flow and safety.

Integration with existing racking: If you plan to support pallet racking above or below, confirm compatibility—steel mezzanine floor system for pallet rack supported warehouse.

Installation timeline and disruption: A prefabricated, bolted system typically installs faster than on-site fabrication.

Regulatory compliance: Building codes, fire safety and occupational health standards must be met.

Budget vs ROI: Compare cost of mezzanine floor system vs relocation or expansion; take into account increased capacity and workflow efficiency.

Package and shipment of mezzanine floor system

The warehouse industrial mezzanine floor system is a strategic investment for facilities seeking to expand vertical capacity, streamline operations and avoid costly build-outs. By choosing a system that is customised to your load, layout and workflow—using concepts such as a warehouse industrial mezzanine floor system installation guide, multi-tier warehouse mezzanine platform for storage expansion, and steel mezzanine floor system for pallet rack supported warehouse—you unlock latent space, support growth, and enhance operational efficiency.

If you are looking to transform underutilised headroom into valuable operational area, consider contacting us to evaluate your building, storage needs and access requirements. With the right system in place, you gain additional floor area, better utilisation and improved flexibility for future changes.

.jpg)