1. Beam pallet racks

Cross-beam pallet racks are safe and convenient, suitable for various warehouses, for direct access to goods. It is the simplest and most widely used shelf. The pallet rack can make full use of space. The convenient pallet access method is adopted to effectively cooperate with forklift loading and unloading, greatly improving operating efficiency. Mechanical equipment requirements: counter-balanced forklift or stacker. The forklift can increase the utilization rate of ground space by 30%, and the operating height can reach more than 16 meters.

Features of beam pallet racks:

Smooth inventory rotation. Provides 100% selection capability. Increase average pickup rates. Provides premium product protection. Because beam pallet racks are suitable for warehousing goods with many varieties and large batches, more lanes are designed to facilitate access, so the ground usage rate is relatively low.

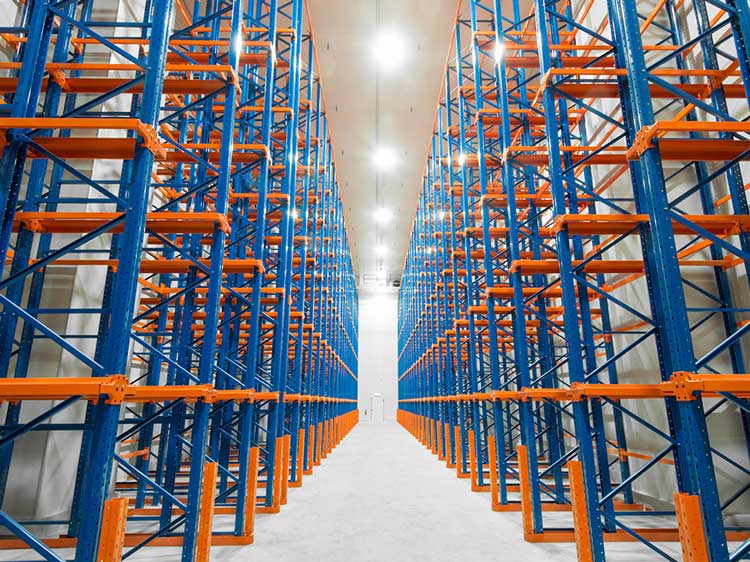

2. Drive through racks

Drive through racks are also called drive-in racks. Designed for storing large quantities of similar palletized goods. The pallets are stored on the support rails one by one in-depth direction, which increases the storage density and improves space utilization. This kind of warehouse rack is usually used in situations where storage space is expensive, such as refrigerated warehouses.

Drive through racks have four basic components: frame, guide rail support, pallet guide rails, and diagonal tie rods. This kind of rack warehouse has a high utilization rate and can realize first-in-first-out or first-in-last-out. Suitable for storing large quantities, small variety of goods, and batch operations. Provides maximum storage in the smallest amount of space available. It is suitable for storage operations of large quantities and small varieties of goods. The forklift can drive directly into the cargo lane to store and retrieve goods, making the operation extremely convenient.

Mechanical equipment requirements: Characteristics of counter-balanced forklifts or forklift racks. Suitable for storage with low inventory flow; can provide 20%-30% optionality; used in warehouses with low pickup rates. Ground usage rate: 60%, higher (needs to be calculated based on the above design).

3. Gravity racks

Compared with ordinary pallet racks, gravity racks do not require operating channels, so the space utilization rate is increased by 60%; pallet operations follow the first-in, first-out principle; automatic storage rotation; the separation of storage and picking greatly increases the output, because It is self-gravity that makes the goods slide, and there is no operating channel, so the number of transportation routes and forklifts is reduced.

Guide rails with a certain slope and tracks are installed on the channels on each floor of the shelf. Under the action of gravity, the unit goods entering the warehouse flow from the storage end to the outbound end. In such a warehouse, there are no working channels between rows, which greatly improves the utilization rate of the warehouse area. However, when using it, it is best that the goods in the same row and on the same layer should be the same goods or goods that are put in and out of the warehouse at the same time. The layer height is adjustable and equipped with various types of forklifts or stackers, which can realize quick access to various pallets. The maximum load capacity of a unit cargo compartment can reach 5000kg. It is the most commonly used storage method in all walks of life.

4. Cantilever racks

Cantilever racks are suitable for storing long goods and irregular goods. The forward-extending cantilever has a light structure and good load capacity, and can greatly improve warehouse utilization and work efficiency when storing irregular or special-length materials.

After adding racks, it is especially suitable for warehouses with small space and low height. It has convenient management and a wide field of view. Compared with ordinary storage racks, the utilization rate is higher.

5. Mezzanine floor

Mezzanine floors have a fully modular structure. Wooden boards, pattern boards, steel plates, and other materials can be used as floor slabs. They can be flexibly designed into two or more layers and are suitable for hardware tools. Storage of small packages of electronic equipment, mechanical spare parts, and other items, making full use of space for storing goods of many varieties and small batches. It is suitable for situations where the site is limited, the variety is large, and the quantity is small. It can increase the utilization rate several times on the existing site and can be operated with a lift.

Fully modular structure, special light steel floor slab, low cost, and fast construction. According to the actual site and needs, it can be flexibly designed into two floors or multiple floors to fully utilize the space. Among them, special racks include six categories: mold racks, oil drum racks, flow racks, grid racks, aerial vehicles, and net partitions. The ones are more common racks.

6. Carton flow racks

Carton flow racks: Use fluent strips to put goods into plastic boxes or turnover boxes, using the weight of the goods to realize first-in, first-out. It is suitable for storing materials on production lines or assembly lines. The material boxes can slide down the rollers by gravity.

7. Radio shuttle racks

Features of the radio shuttle rack:

The forklift does not need to enter the tunnel, which saves time, improves the safety of personnel and goods, greatly improves the efficiency of goods access in the warehouse, and makes full use of the warehouse space.About 80% to 85% of the space in the warehouse can be used; suitable for different types of products can be stored flexibly in layers; compared with drive in racks, the structure of radio shuttle rack is stable and has a high safety factor. It can realize first-in-first-out and first-in-last-out; it can be automatically sorted and inventoried.

Post time: 10-16-2023