In modern warehouses and distribution centers, pallet racking systems are essential for maximizing storage capacity and operational efficiency. However, high forklift traffic, tight aisles, and heavy pallet loads significantly increase the risk of rack damage. Implementing a comprehensive pallet rack protection strategy is critical to safeguarding racking structures, stored goods, and personnel.

This guide explains how pallet rack guards, rack protectors, and related racking protection barriers help reduce damage, improve safety, and extend the service life of pallet racking systems.

What Is Pallet Rack Protection?

Pallet racking protection refers to a range of protective components designed to shield vulnerable areas of pallet racking from impact, misalignment, and load-related stress. These systems focus on protecting uprights, columns, aisle ends, and pallet placement zones where damage most frequently occurs.

A well-designed pallet rack guarding solution addresses common risks such as:

• Forklift collisions with rack uprights

• Improper pallet positioning on beams

• Impact at aisle ends and rack corners

• Structural weakening of load-bearing columns

By combining multiple rack protection guards, warehouses can significantly reduce repair costs and safety incidents.

Pallet Positioning: The Foundation of Rack Safety

Pallet positioning plays a critical role in maintaining rack stability. When pallets are not properly aligned on beams, they can shift, fall, or overload specific rack components.

Pallet positioning aids—such as pallet stops and positioning rails—help ensure pallets are placed correctly every time, reducing the risk of product damage and improving overall pallet protection.

Key benefits of pallet positioning systems:

• Improved load stability

• Reduced risk of pallet push-through

• Increased operator confidence during handling

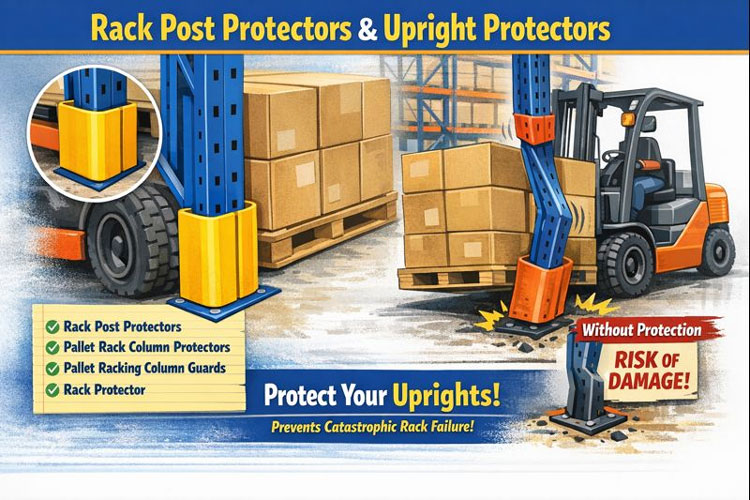

Rack Post Protectors and Upright Protectors

Rack post protectors are among the most widely used pallet rack protectors. Installed at the base of uprights, they absorb and deflect impacts from forklifts and pallet trucks before structural damage occurs.

Also referred to as upright protectors or pallet rack upright guards, these components are essential because rack columns carry the majority of vertical and horizontal loads.

Common terms used for these solutions include:

• rack post protectors

• pallet rack column protectors

• pallet racking column guards

• rack protector

Protecting uprights significantly reduces the likelihood of catastrophic rack failure.

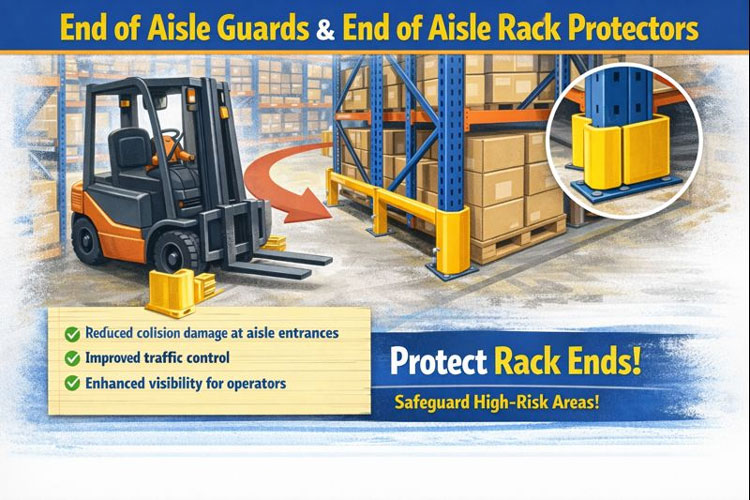

End of Aisle Guards and End of Aisle Rack Protectors

Aisle ends are high-risk zones due to turning forklifts and frequent traffic flow. End of aisle guards and end of aisle rack protectors create a physical barrier between vehicles and rack structures.

These heavy-duty guards are anchored to the floor and positioned in front of rack ends, preventing direct impact on uprights and beams.

Advantages include:

• Reduced collision damage at aisle entrances

• Improved traffic control

• Enhanced visibility for operators

Pallet Racking Barriers and Protection Barriers

In high-traffic warehouses, pallet racking barriers and racking protection barriers provide an added layer of safety by separating vehicle lanes from storage areas.

These barriers are ideal for:

• Main forklift routes

• Cross-aisle intersections

• Pedestrian-adjacent storage zones

By acting as a physical buffer, barriers enhance overall rack protection and help enforce safe traffic patterns.

Comprehensive Pallet Rack Guarding Systems

A complete pallet rack guarding solution often combines multiple protective elements, including:

• Pallet rack guards for uprights and columns

• End-of-aisle rack protectors

• Pallet positioning components

• Racking protection barriers

These integrated systems may also be referred to as a pallet rack protector or protection rack setup, designed to provide full-spectrum defense against impact-related damage.

Why Pallet Rack Protection Matters

Investing in high-quality pallet rack protection delivers long-term operational benefits:

• Lower rack repair and replacement costs

• Reduced downtime caused by structural damage

• Improved warehouse safety compliance

• Extended lifespan of pallet racking systems

• Greater protection for stored inventory

Properly installed pallet rack guards and racking guards help maintain the structural integrity of the racking system even in demanding warehouse environments.

Conclusion

Pallet racking systems are only as reliable as the protection measures supporting them. From pallet positioning and rack post protectors to end of aisle guards and pallet racking barriers, each component plays a vital role in warehouse safety and efficiency.

By implementing a tailored pallet rack guarding strategy with the right rack protectors, warehouses can minimize risk, protect assets, and ensure long-term operational stability.

For customized pallet rack protection solutions and professional guidance, Aceally provides reliable systems designed to meet the demands of modern warehousing. Our protective devices safeguard equipment in industrial settings from damage and misuse. For more information on pallet racking protective devices to protect your warehouse racking equipment, please get in touch with us.