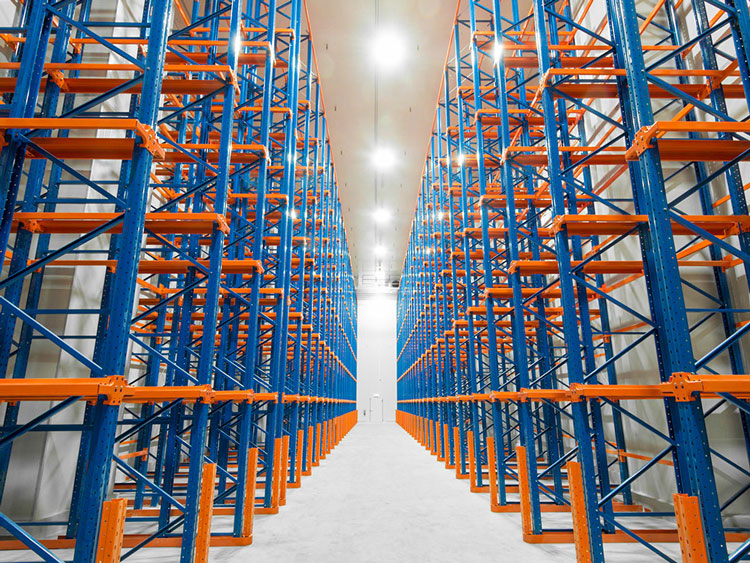

Drive-in racking allows forklifts to drive right inside the aisles to deposit or retrieve pallets. Ideally suited to bulk storage of like product, and is very good value on a cost per pallet space basis. It is very popular with bulk producers like dairy factories where one production batch will fill one or multiple aisles with the same product. There are no cross support beams with drive-in racking so pallets will be of a specified user standard size.

Our system can hold pallets, wire bins, long material such as bars, rolls of carpet, packets of timber, etc., therefore, providing an extremely wide variety of uses. The downside is selectivity drops to about 30%. This is not an issue when storing big quantities of like products. Often used in freezer environments, where First In Last Out (FILO) doesn’t matter, and high space utilization is critical. To remove the pallet that was loaded in first, all pallets in front will have to be removed.

Drive-in pallet racking works with forklifts driving to the end of an empty aisle to deposit the first pallet. Pallets are stored 2 to 12 deep and sit on centering rails on extended ledges along both sides of the aisle. This system requires a fairly narrow forklift. Generally, any modern forklift up to 1.8 tonnes will fit easily. A standard pallet width is 1200mm. If larger pallet widths are used then a larger forklift can be used. What you find is that specific industries often have a pallet size that is standard to the industry, such as the fertilizer industry seems to use 1400 wide pallets, and the printing industry uses smaller pallets. You will need a forklift under 1100 wide to load 1200 wide pallets. Forklifts don’t come much narrower than 1100mm so if you want a drive-in system for smaller than standard pallets you will need to sit your small pallet on a standard pallet to make it work.

Post time: 05-23-2022